Summary of NBC 2016 Part 4 Fire and Life Safety

Bureau of

Indian Standards (BIS) is the National Standards Body of India established

under the BIS Act 2016 for development of standards, marking and quality

certification of goods and for matters connected therewith or incidental

thereto.

The National

Building Code of India 2016 (NBC 2016), a comprehensive building Code prepared

by BIS, is a national instrument providing guidelines for regulating the

building construction activities across the country.

Thus, the

Code gives all the information required by the architect, engineer, structural

engineer, construction engineer, services engineer and other professionals from

the early stages of planning to translating the building on to terra firma. The

comprehensive NBC 2016 contains 13 Parts some of which are divided into

Sections and Subsections totalling 33 chapters.

Key Content - Fire and Life Safety

All buildings shall satisfy minimum requirements for safety of life from fire, smoke, fumes or panic arising from these or similar causes.

Classification of buildings based on occupancy

The city or

area under the jurisdiction of the Authority shall be demarcated into distinct

fire zones depending upon the existing layout, types of building construction,

classification of existing buildings based on occupancy and expected future

development of the city or area. Intermixing of hazardous occupancies should

not be allowed in other zones.

1) Fire

resistant walls, floors and compartments

• To limit

the spread of fire

• No

compromise for openings such as shafts, refuse chutes, vertical openings, etc.

2) Shafts

• To be

provided with fire resistant rated inspection door for passage of building

services such

as cables, electrical wires, telephone cables, plumbing pipes, etc

depending

upon location.

3) Refuge

area

• An area

within the building for a temporary use during egress. It generally serves as

a staging

area which is protected from the effect of fire and smoke.

4) Fire

detection and firefighting installations

• These

include fire alarm, fire extinguishers, hose reels, wet riser, down comer,

yard

hydrants, sprinklers, deluge system, water spray, foam, water mist systems,

gaseous or

dry powder system, water storage tanks and pumps, etc.

5) Means

of egress

• Consists of

three separate and distinct parts, that is, exit access, exit and exit

discharge

• Exit access

are working/functional areas

• Various

types of exit access and exits are doorways, corridors and passageways,

horizontal exits, internal staircases, exit passageways, external staircases

and ramps.

6) Firefighting

shafts

• With fire

man talk back, fire door, wet riser, hose reel, signage showing floor plan and

stairways and fire man’s lift

Fire prevention

Fire prevention is based on the following:

•

Occupancy

•

Fire zones

•

Types of construction

•

General requirement of all occupancies

•

Electrical installation

a.

Emergency power for fire and life safety system

b.

Substation

c.

Lightning protection

d.

Escape lighting and exit signage

e.

HVAC and smoke control

f.

Glazing

g.

Surface interior finish

h.

Fire Command Centre

•

Fire resistance rating of structural and

non-structural elements updated

•

Fire resistance rating of service shaft and duct

opening of 2 hours. Inspection

door and duct opening should have same resistance rating of service shaft.

•

Facade protection and openable windows in facade shall

have fire protection and smoke exhaust aspects

•

Compartment criteria of different occupancies and fire

separating wall & floor partitions are modified

•

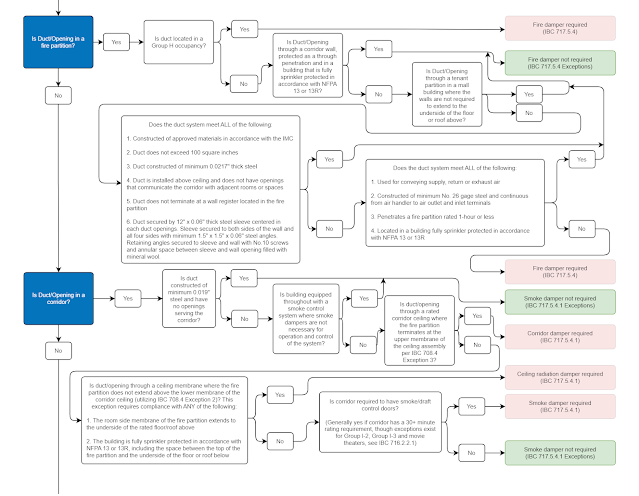

Provision of fire/smoke damper design more elaborated

like provision of damper

A. At

the fire separation wall

B. Where

ducts/passage enter the vertical shaft

C.

Where the duct passes through floor

D. At

the inlet of supply air duct and return air duct of each compartment on every

floor.

Glass facade

- For

fully sprinkler building having fire separation of 9 m or more, tampered

glass in a non-combustible assembly with ability to hold the glass in

position shall be provided

- It

shall be ensured that sprinklers are located within 60 cm and there is

full coverage of glass. All the gaps between floor slab and facade

assembly shall be sealed at all level by fire resistant sealant material

of equal rating of floor slab to prevent fire and smoke propagation from

one floor to another.

- Openable

panels shall be provided in each floor and shall be spaced not more than

10 m apart, measured along the external wall from the centre to centre of

the access opening. Such opening shall be operable at a height between 1.2

m and 1.5 m from the floor in the form of openable panel (Fire Access

Panel) not less than 1000 mm x 1000mm opening outward.

FIRE OPENABLE PANEL DO NOT OBSTRUCT IN 25 mm lettering in the inner side can also

act as smoke exhaust at the time of distress.

Service Sector in Focus

Some important features considered in Hospitals

•

Each compartment shall be able to accommodate patients

from adjoining compartment and Density Factor (Number of patient) area to be

allotted 3.5 sq.m/person

•

Critical patients, incapable of self-preservation and

physical impairment shall be housed within 30 m height

•

Other types of patient and occupancy like Nurses’

centre, Medical shop, Canteen, etc to be in between 30-45 m in height

•

Operation theatre, Delivery room, ICU, Recovery room

shall have a separation with 2 hours of fire resistance rating

•

Passage width of aisles, corridor, ramp, etc shall be

2.4 m unobstructed through which patients are being moved and in case of

inpatient width not less than 1.5

•

All exits from Hospital or Infirmary Section shall not

be less than 2m

•

Minimum door width single/double occupancy shall be

1.25 m; for 3-5 patients, door width shall be 1.50 m; for more than 5 patients

and patient evacuation bed (i.e. ICU) it shall be 2.0 m; for single/double

doors, it shall be 1.5 m

•

Any sleeping accommodation or suite exceeding 100 sq.m

in area, 2 no.s of access door leading to escape route, corridor, etc to be

provided

•

Room designed for laboratory or like facility shall be

limited to 100 sq.m in area for additional area coverage. Fire separation shall

be done by 2 hours fire resistance.

•

A stretcher lift in the lift bank shall also act as a

fireman lift

Life safety is based on:

•

General exit

•

Occupant load

•

Declaration of occupant load

•

Egress components

•

Smoke control of exit

•

Compartmentation

•

Smoke control above and below ground

•

Gas supply

•

Hazardous area

•

Fire detection

•

Fire drill

Safe electrical supply system

•

The electrical supplies towards the critical aspects

of emergency power for fire and life safety addressed for respective system.

•

Power supply to the panel and distribution board be

through fire proof enclosure or circuit integrity cable or through alternate

route in the adjoining fire compartment is protected within the compartment of

vulnerability and require location of the panel/distribution board feeding

shall be in fire and safety zone and ensure supply of power to these system.

•

The high voltage electrical equipment safety including

aspects of emergency and exit lighting of large and public assembly occupancies

•

HVAC system, smoke control and mitigation also to be

taken care of with comprehensive approach towards compartmentation and spread

of fire and smoke.

Life safety

•

To calculate the number of exit requirement with

Density Factor

•

Exit Layout for better understanding of various

aspects of means of egress, corridor, passageways, stair ways and exit

•

Provision for access control door, electromagnetic

door, revolving door and turnstile (conditions to be fulfilled)

•

Provision of handrail at both sides of stairs and ramp

width exceeding 1.5m

•

Internal stair width of residential building increased

to 1250 mm from 1000 mm

•

External stairs width increased from 1250 mm to 1500

mm

•

Each fire rated door shall have a marking on the

product of its certification. Door assembly parts like hinges, locks, panic

bars, door closer and door viewer shall be certified.

•

Updated staircase pressurization requirement (Smoke

control of exit) for lobbies & corridors

•

Smoke exhaust and pressurization of area below the

ground floor

•

Requirement of smoke exhaust system having make up air

system for the theatre and atrium

•

Smoke exhaust fan in the mechanical ventilation system

shall be fire rated of 250 degrees centigrade for 2 hours (120 minutes)

•

Provision of smoke barrier and sprinkler around the

opening for escalator

•

Requirement of display of occupancy load for assembly

occupancy and call center.