INTERPRETATION & INSTALLATION REQUIREMENTS

What is a Style “A” Loop? What is a Style “B”

Loop? What is a Style “C” Loop?

First off, don’t get confused between “Class” and

“Style”! “Style” refers to the functionality of communications loops

between Listed control panels, transponders, and field devices (provided to the

loop controller through a combination of the system’s firmware or software and

strategically placed isolators). “Class” refers to the wiring scheme used

to interconnect them. A Style “A” and Style “C” loop are actually wired

identically in a Class “A” scheme. Both Style “A” and Style “C” loops

have an independent return path which becomes an alternate means of

communicating with connected control units, transponders and field

devices should a portion of the loop become compromised by an “open” on the

circuit. Style “C” loops however, provide a higher level of functionality

when the loop becomes compromised by a short

circuit on

the wiring. A Style “C” loop is a continuous Class “A” type circuit that

goes from one floor area to another without interruption. A Style “A”

loop is limited to one floor area (and doesn’t usually require isolators as

it’s powered by a dedicated loop controller). In a Style “B” loop, an

“open” (or short) will sever communications with any control unit (or

transponder) wired in the shorted circuit.

Field devices are wired either Class “A” or Class

“B” in a floor area. To add to the confusion, you can also “T” tap within

the same floor area when you’re using addressable field devices or route both

the return and primary loops into a single five conductor cable assembly in

certain circumstances which are illustrated within the Installation Standard.

Table 1 in CAN/ULC-S524-14 serves to illustrate the

various pros and cons of the different “Styles” utilized in the communications

between control panels and transponders (it also provides the means for the

Verifier to identify whether-or-not the correct response occurs when a short is

imposed on the communications loop between control panels and

transponders). A Style “B” type loop is NOT ALLOWED in Canada for a DCL riser

between control units or transponders, but it IS ALLOWED between

buildings in a Campus Style Network. Class “B” wiring

is NOT ALLOWED for a DCL or a Power Buss common riser

between a control unit and connected active (or supporting) field devices.

CLASS “A” CONNECTED FIELD DEVICES:

In order for isolators to work properly in this

type of configuration, the “out” side of the first unit on the floor area must

face the “out” side of the last unit on the floor area. An exception

exists for isolators that may employ bi-directional communication

protocols. You should definitely check the manufacturer’s information and

installation guide. Either way, if they identify an “in” and an “out”,

you can’t go wrong. A short anywhere on the floor will result in both isolators

activating which limits the loss of data/power to only the devices in that

single area. This having been said, it must be noted that isolators

employed on a DCL “A” loop will only have a single wire connected under

each terminal, positive “in”, negative “in”, positive “out” and negative

“out”.

This photograph depicts an isolator

terminated in a DCL “A” loop that’s wired incorrectly.

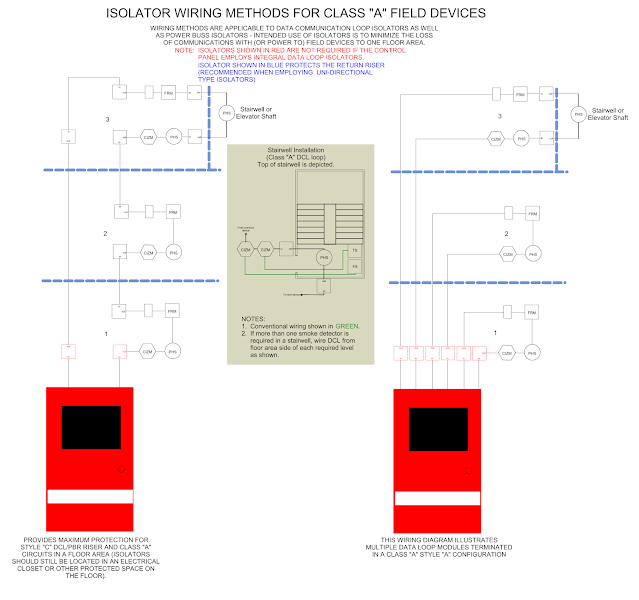

You will note that, in both our wiring circuit

diagrams, there is an additional isolator added to the mix, which the diagram in

the 2014 version of the Installation Standard does not include. This unit

protects the return side riser between the common control and

the last floor area. Please note that if the control panel’s DCL/PBR loop

is equipped with on-board isolators, the first two units immediately shown in

line from the common control (which we’ve highlighted in RED) are not required. Please

ensure that the control panel’s documentation clearly identifies that the

DCL/PBR loop is isolated (and indicates the configuration)! An exception

to this rule exists where the manufacture may RECOMMEND the installation of

isolators in this location as a means of preserving the integrity of the loop

controller over the life of the fire alarm system.

Class “A” DCL/PBR loop wiring diagram (both Style “A” and Style “C”

loops are illustrated)

CLASS “A” LOOP RISER WITH CLASS “B” CONNECTED FIELD

DEVICES:

In order for isolators in this configuration to

operate as intended, both “out” sides of the two isolators installed in the

floor area are “T” tapped to the Class “B” wired devices on the floor.

There is an additional wiring method which is perfectly suited to a control

panel replacement within a building where a traditional conventionally zoned

fire alarm system was installed. Both methods are illustrated in the

diagram in below image.

TESTING/SERVICE

The testing methods vary slightly depending upon

the type of isolator (as well as who manufactured it). It’s a good idea

to have the installation instructions handy for the model of isolator you’re

testing. This will usually include a recommended test procedure that

might differ slightly from what you read here.

NOTE:

The manufacturer’s suggested test methods should be used in EVERY case.

SLC (Signalling Line Circuit) or DCL (Data

Communication Line) Isolators:

Testing method -

There are two termination points on every isolator. One is an “in” from

the common data loop and the other is an “out” to the field devices it

serves. Short the “out” side to ensure the unit functions correctly (yes,

this means that you will have to remove the cover on each unit!).

Depending on the number of devices on the “out” side, you should see a string

of error messages on the common control that are most commonly identified by

the phrases “missing device” or “device error”, or “data loop short”.

Maintain the short until you have scrolled through and noted each device that

fails to report. Part of your “test” ensures that the total number of

devices for each isolator does not exceed the manufacturer’s maximum

limit. If more than one floor area’s devices fail to report while the

short is in place you will have to note this as a deficiency on your

report! If the isolator you’re testing happens to be bi-directional

proceed to short the “in” side. Maintain the short until your helper has

scrolled through and noted each device that fails to report. The other

part of the test (with the short still in place) requires you to proceed to

another floor area and initiate an alarm from there.

Field devices which employ isolator bases must also be tested. If

the system you’re testing employs these units (it’s usually the first smoke

detector on the loop), you’ll have to find an addressable device (a manual

station is usually the easiest to access) downstream of the isolator.

Drop it and short the loop terminals from here. Maintain the short and

have your helper scroll through and note each device that fails to

report. Again, you’ll have to perform the alarm test component from a

field device located outside of the shorted zone.

Power Supply & Audio Riser Buss Isolators:

Testing method -

While shorting a power supply (or audio output circuit) is not normally

recommended, opening the circuit on the “out” side of the isolator will

identify the devices it protects. You must ensure the maximum current for

the unit is not exceeded (or the recommended maximum number of devices).

Use your meter (set to “amps”) to determine what each isolator is

handling. In EVERY case, follow the manufacturer’s suggested

test methods and note the results in your report.

Suite Signal (Bell/Buzzer Circuit) Isolators:

Normally these units are installed in the common

area corridor outside of the suites they serve. They’re always located

behind a suitable cover which identifies them as a fire signalling component or

fire alarm device. There are two “flavours” available: “supervised”

and “unsupervised”, The unsupervised isolator is NOT allowed by Code or

the installation standard (CAN/ULC-S524) despite the fact that the devices may

be ULC Listed! If you come across one (they will have a label affixed to

them identifying them as such), you must fail the unit. No further

testing is required.

Testing method -

There are two phases to the required testing. One is performed while the

system is in normal supervisory mode, the other is performed while the system’s

sounders are active. For these tests, it is recommended they be performed

inside the suite the unit serves. You will notice that there are two

“outputs” on each isolator (it serves two separate suites or units). All

in-suite devices controlled by an isolator are wired in a Class “A” loop.

Step 1 - Remove the

cover from the isolator to expose the wiring terminals.

Step 2 - Identify the common NAC circuit input and output terminals from the

fire alarm control panel.

Step 3 - Perform the circuit testing required of any notification appliance

utilizing these terminals. Replace the cover when the testing is

complete.

Step 4 - Remove and drop any one of the in-suite buzzers.

Step 5 - Disconnect one of the terminals (or terminal leads). You should

receive an “open” fault at the common control. If the isolator you’re

testing happens to be a Potter/Amseco IS-S, then one of the LED’s should also

illuminate on the cover. With the wire disconnected, have your partner

initiate a “drill test”. The buzzer in your hand (and all the buzzers in

the suite) should sound. This is the supervisory test and Class “A”

operational test for the buzzers in the suite.

Step 6 - Reconnect the terminal.

Step 7 - Now short positive and negative together. Observe the display on

the common control (as well as on the isolator - if applicable) and note

it.

Step 8 - With the short still on, have your helper initiate a fire drill

test. None of the buzzers in the suite should be sounding, but the

buzzers on the other side of the isolator (as well as the other suites on the

floor) should be unaffected.

Step 9 - With the system still in active “drill test”, REMOVE the short.

The buzzer in your hand should start to sound.

Step 10 - Reinstate the short. The buzzer in your hand (as well as any

others in the same suite) should all stop sounding. The buzzers in the

other suite served by the isolator should continue to sound.

Step 11 - Have your helper deactivate the “drill test”.

If all of the above tests are completed satisfactorily, you can move on

to the next suite on the floor (after reinstalling the buzzer that is!).

NOTE: If, in step 8, none of the buzzers in the suites sound, then the notification appliance circuit is programmed incorrectly! You must ensure this is corrected before proceeding with the testing of the rest of the insuite appliances. Some systems utilize a jumper setting to activate the signals if isolators are on the circuit. Other systems require access to the physical panel programming to enable this feature.

it is really amazing...thanks for sharing....provide more useful information...I am expecting more interesting topics from you. And this was nice content and definitely it will be useful for many people.

ReplyDeletefire fighting sprinkler system manufacturer in Maharashtra

Nice blog!

ReplyDeleteAre you searching for a service center in Dubai for your Macbook?? Scorpionfix is here, one of the best Apple service center in Dubai.

Surface pro 8 repair in Sharjah

Surface pro service center Sharjah

Surface pro service center Dubai

Macbook repair in Sharjah

Macbook repair in Dubai.

Laptop repair in Dubai

Laptop repair in Sharjah

Surface pro 8 repair in Dubai

macbook service center abu dhabi

macbook repair abu dhabi

Laptop repair abu dhabi

Laptop service center abu dhabi

Apple service center Sharjah