Short note to Intrinsic Safety

In the many industrial processes where flammable materials are handled, any leak or spillage may give rise to an explosive atmosphere. To protect both personnel and plant, precautions must be taken to ensure that this atmosphere cannot be ignited. The areas at risk are known as ‘hazardous areas’ and the materials that are commonly involved include crude oil and its derivatives, natural and man-made process gases, alcohols, dusts, carbon dust, flour, starch, grain & fibres.

At one time, pneumatic control was widely used in such environments for its inherent safety but, although much pneumatic equipment is still in use in many parts of the world, it is now seldom chosen for new instrumentation systems due to its limited capability.

Intrinsic

safety is achieved with the use of a Zener Diodes which limits voltage,

resistors that limit the current and a fuse to cut off electricity. Equipment

or devices that may be made intrinsically safe must first be approved for use

in an intrinsically safe system through a competent authority, such as

the National Fire Protection Agency (NFPA), the Canadian

Standards Association (CSA), Underwriters Laboratories (UL), Factory

Mutual (FM), National Electric Code (NEC), and the Instrument

Society of Measurement and Control (ISA).

To enable electrical equipment to be used in hazardous areas, eight different ‘explosion-protection’ techniques have been developed over the years. National or international standards and codes of practice govern each technique and define in detail how the equipment should be designed and applied. National certifying (or approvals) authorities ensure design compliance and national inspectorates (or insurance companies) vet and usually inspect each installation. The different techniques lend themselves to different applications and, for instrumentation used in process measurement and control, the two leading techniques are the use of ‘flameproof enclosures’ and ‘intrinsic safety’.

With the flameproof technique, known as ‘explosionproof’ in the USA and Canada, hazardous-area equipment is surrounded by a strong enclosure which can withstand internal explosions without igniting the external atmosphere. This technique, which has been in use for over 80 years, allows high power levels but has the disadvantages that the enclosures are heavy and expensive and must not be opened without first disconnecting the electrical circuit or obtaining a ‘gas-free certificate’ for the relevant plant area.

By

contrast, in the case of the IS technique, the electrical energy in

hazardous-area circuits is deliberately restricted such that any electrical

sparks or hot spots that may occur are too weak to cause ignition. This is

achieved by inserting an energy-limiting interface in the wiring between safe

and hazardous areas. The interface passes signals in either direction as

required but limits the voltage and current that can reach the hazardous area

under fault conditions. It may be integral with the safe-area equipment or

separate for greater flexibility. First developed in the United Kingdom between

1914 and 1916 for use in coal mines, IS came into its own for other applications

in the early 1960s with the introduction of the ‘shunt-diode safety barrier’

based on the voltage-limiting, Zener diode. Since then, IS has been developed

as a technique and used increasingly until it is now the preferred solution in

most markets.

The main reasons for the continually increasing popularity of intrinsic

safety are as follows:

·

Advances

in semiconductors; allowing increasingly complex electrical operations to be

carried out in hazardous areas at the low power levels permitted – typically in

the order of 1 watt;

·

simple,

light and inexpensive hazardous-area equipment which can be calibrated and

serviced ‘live’;

· the ability to use ordinary instrument wiring in hazardous areas instead of armoured cable and the inherent safety for personnel due to the low voltages employed.

Progressive harmonisation of standards governing the design of IS equipment, is taking place. This will allow the same product to be sold and used in many countries without any variation.

Intrinsic safety is one of the key methods used to protect electrical equipment in hazardous locations, but understanding its nuances can be challenging. In this webinar, we discuss what intrinsic safety is, the types of equipment that use this protection concept, the global requirements and standards applied, and the fundamentals for making a device intrinsically safe.

With a

certified IS interface, safe-area equipment needs no certification and the user

can choose or change the hazardous-area equipment within wide limits. Simple,

‘non-energy storing’ sensors need no certification.

Below trusted brand I.S detector MCP part code:

The main advantage is that it provides a solution to all problems that occur in a hazardous area regarding equipment. It prevents the cost and bulk of explosion proof enclosures, with additional cost savings as a result of the ability to use standard instrumentation cables. Additionally, the maintenance and diagnostic work can be performed without shutting down production and ventilating the work area.

Intrinsic

safety relates to three levels of protection, ‘ia’, ‘ib’ and ‘ic’ that aim to

balance the probability of an explosive atmosphere, assessing the probability

of whether that is an ignition capable situation that may occur.

‘ia’

Offers the highest level of protection

and any equipment that is given this level is generally considered adequately

safe for use in the most hazardous locations (Zone 0) with two faults.

‘ib’

This level is considered adequately

safe with one fault is considered safe for use in less frequently hazardous

areas (Zone 1).

‘ic’

This level is given for ‘normal operation’ with a unity factor of safety is generally acceptable in infrequently hazardous areas (Zone 2).

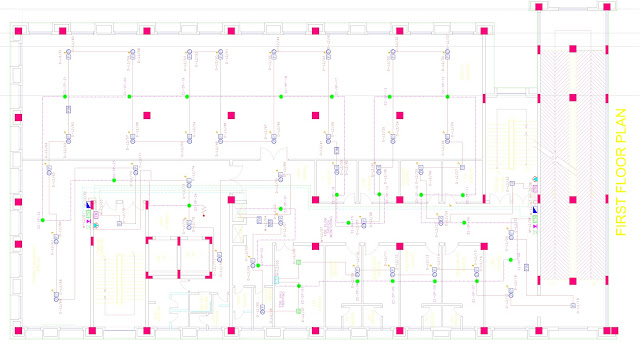

%20R%20&%20D%20FIRST%20FLOOR%20LOOP%20-%208.jpg)