|

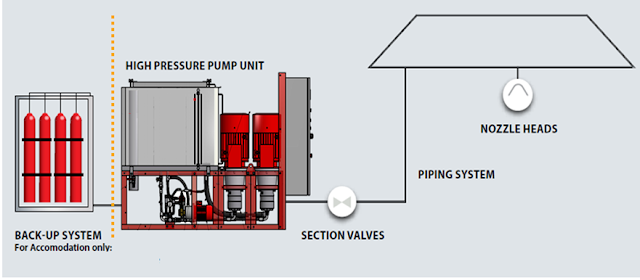

E.M Check list for High Pressure Fire Misting System ( High Pressure & Booter & Jockey Pumps , Deluge, wet )

|

|

1

|

Change

operation mode of 15 pumps to off mode

|

|

2

|

Turn on

manually pump# 1, after pump pressure reach upto 140 bar, check & fill

column of P#1 which is the below mentioned

|

|

3

|

Turn

off pump#1, reduce the pressure to

100 bar

|

|

4

|

Turn on

manually pump# 2 after pump pressure reach upto 140 bar, check & fill

column of P#2 which is the below mentioned

|

|

5

|

Repeat

the above mentioned for 13 remaining pumps

|

|

6

|

When

pressure reach to 140 bar solenoid valve must be opened

|

|

7

|

To ensure that safety valve open at 160 bar, close manual valve or

disconnect power of solenoid valve & pressure valve for increasing of

pressure upto 160 bar

|

|

8

|

Take

pressure reading from control panel & mech pressure gauge, for flow rate

read from control panel

|

|

9

|

Change

operation mode of 15 pumps to auto mode

|

|

10

|

Make

drain to reduce pressure under 20 bar, ensure that three pumps will start one

by one each one second

|

|

11

|

After 15

second if the pressure does not reach 100 bar other three pumps will start

|

|

|

|

|

S.N

|

item

|

P#1

|

P#2

|

P#3

|

P#4

|

P#5

|

P#6

|

P#7

|

P#8

|

P#9

|

P#10

|

P#11

|

P#12

|

P#13

|

P#14

|

P#15

|

|

|

|

|

set #1

|

set#2

|

set#3

|

|

|

1

|

Check E/M

consultants inspection requests, there aren’t

comments

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2

|

Check

pump frame

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1

|

Check for

abnormal noise &vibration

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2

|

Check for

any leakage from pump, connection & fittings

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3

|

Check

pump pressure, it must reach upto 140 bar

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4

|

Check

soleniod valve for overflow

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5

|

Safety

valve / open at 160 bar

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6

|

Are

safety valve drain connected to return line to tank

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7

|

Manual

air drain

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8

|

Non

return valve

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

9

|

Strainer

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

10

|

Record

running current value

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

11

|

Check

overload relay ( by reduce setting value) or remove wire No. (96 or 95)

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

12

|

Check

phase failure relay remove wire No. (11 or 14)

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

13

|

Check

contactor, termination no loss, no heat

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

14

|

Check

indication lamps & selector switches

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

15

|

Pump

running signal sent from fogtech to fire control panel

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

16

|

General

fault signal sent from fogtech to fire control panel

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

17

|

Pressure

valve#1/ open at 140 bar

|

|

|

|

|

|

18

|

Pressure

valve#2/ open at 140 bar

|

|

|

|

|

|

19

|

Differential

pressure switch 0.6 bar

|

|

|

|

20

|

Differential

pressure switch 0.8 bar

|

|

|

|

21

|

Pressure sensor

|

|

|

|

|

|

22

|

Flow

sensor

|

|

|

|

23

|

Pressure

sensor for manifold #1

|

|

|

|

24

|

Pressure

sensor for manifold #2

|

|

|

|

25

|

Pressure

sensor for main pipe

|

|

|

|

26

|

Tank

level sensor

|

|

|

|

Deluge system

|

|

|

the below are connected to fire control

panel

|

|

|

1

|

Location:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2

|

Valve tag

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3

|

Limit

switch for manual valve

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4

|

Solenoid

valve

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5

|

Limit

switch for drain valve

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6

|

Check

pipes are supported properly

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7

|

Check

nozzles location no obstruction for its job

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8

|

Check

manual valves

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

9

|

Limit

switch for F.H.C

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Wet system

|

|

|

the below are connected as per mentioned

|

|

|

1

|

Location:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2

|

Valve tag

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3

|

Limit

switch for manual valve/fire control panel

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4

|

Flow

switch / control panel.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5

|

Check

pipes are supported properly.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6

|

Check

nozzles location no obstruction for its job.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7

|

Check drain

line.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8

|

Check

manual valves.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Interface between Fire Control Panel &

fogtech panel

|

|

|

|

Pump

starting signal sent from fire control panel to dedicated panel

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Alarm

signal sent from dedicated panel to fire control panel that dedicated has problem

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Jockey pump

|

|

|

1

|

Check E/M

consultants inspection requests, there arent

comments

|

|

|

|

2

|

Check

pump frame

|

|

|

|

3

|

Check for

abnormal noise &vibration

|

|

|

|

4

|

Check for

any leakage from pump, connection & fittings

|

|

|

|

5

|

Check manual valves

|

|

|

|

6

|

Check nonreturn valve

|

|

|

|

7

|

Pressure gauge

|

|

|

|

8

|

Record

running current value

|

|

|

|

9

|

Check

overload relay (by reduce setting value) or remove wire No. (96 or 95)

|

|

|

|

10

|

Check

phase failure relay remove wire No. (11 or 14)

|

|

|

|

11

|

Check

contactor, termination no loss, no heat

|

|

|

|

12

|

Check

indication lamps & selector switches

|

|

|

|

13

|

Check

that pump will automatically start under 33 bar , turn off at 35 bar

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Booster pump

|

|

|

|

|

pump#1

|

pump#2

|

|

|

1

|

Check E/M

consultants inspection requests, there arent

comments

|

|

|

|

|

2

|

Check

pump frame

|

|

|

|

|

3

|

Check for

abnormal noise &vibration

|

|

|

|

|

4

|

Check for

any leakage from pump, connection & fittings

|

|

|

|

|

5

|

Check manual valves

|

|

|

|

|

6

|

Check non return valve

|

|

|

|

|

7

|

Pressure gauge

|

|

|

|

|

8

|

Record

running current value

|

|

|

|

|

9

|

Check

overload relay (by reduce setting value) or remove wire No. (96 or 95)

|

|

|

|

|

10

|

Check

phase failure relay remove wire No. (11 or 14)

|

|

|

|

|

11

|

Check

contactor, termination no loss, no heat

|

|

|

|

|

12

|

Check

indication lamps & selector switches

|

|

|

|

|

13

|

Check

that pump will automatically if hp pumps start, that pressure will be 3 bar

|

|

|

|